From Inspection to Maintenance: A Guide to Full-Process Service for Marriott Projects from Exceptional Furniture Manufacturers

Time:2025-08-08Views:427From Inspection to Maintenance: A Guide to Full-Process Service for Marriott Projects from Exceptional Furniture Manufacturers

introduction

Your Frustration:

When Marriott International Group selects furniture suppliers, its assessment criteria go far beyond the product itself - covering the entire chain of service capabilities. We have delivered more than 120,000 pieces of furniture to 18 Marriott hotels around the world, and here's how to ensure the perfect execution of projects with an integrated service ecosystem:

🔍 Phase 1: Transparent Laboratory – In-depth audit beyond the standard

Not only will we inspect the factory, but we will also experience our operational DNA

360° virtual pre-inspection factory: Remotely visit the digital factory through VR technology

Real-time certification signage: Dynamic display of ISO 9001/14001, BIFMA and ENF environmental certifications

Material traceability demo: Scan any sample to see the supply chain trajectory

Cultural Integration Workshop: Co-development of local cultural design (e.g. New Zealand project integrating Māori totem)

Customer Testimonials:

"Blockchain material traceability system convinced the sustainability committee in 5 minutes" – Marriott's Asia Pacific Procurement Director

✍️ The second stage: precision signing - carving a blueprint for success on paper

Smart contract frameworks completely eliminate execution risks

Segmented payment nodes: Deeply bound to production milestones

Late delivery clause: 0.5% of the contract amount will be paid on a daily basis

Change response mechanism: 72-hour curing design modification plan

Kuala Lumpur Marriott case

▸ Contract amount: $2.8 million

▸ Cycle: 98 days from signing to installation

▸ Customization: 47 room configuration plans

"Blockchain material traceability system convinced the sustainability committee in 5 minutes" – Marriott's Asia Pacific Procurement Director

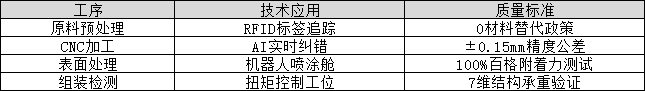

🏭 The third stage: intelligent manufacturing precision - the integration of technology and ingenuity

Industry 4.0 factories transform drawings into perfect finished products

Core intelligent manufacturing system

Sustainable practices

☑️ 93% material utilization

☑️ VOC recovery system that exceeds EU standards

☑️ Solar-powered production line

🔬 Stage 4: Triple Quality Inspection Shield – Beyond Industry Benchmarks

Our inspection standards redefine hospitality quality

Component Pre-Check (Pre-Assembly): Wood moisture content: 8±0.5% Metal parts thickness tolerance: ±0.1mm

White glove assembly inspection: Drawer slide pull: ≤2 Newtons Door panel gap deviation: 《 0.5mm

Destination Mock Test: 72-hour salt spray corrosion test of the coastal project A three-axis vibration test simulating 8,000 km of sea transport

Results: Project delivery defect rate of 0.28% (industry average 2.1%)

🌐 Stage 5: Global logistics - the last mile

Your furniture is delivered worldwide directly to the installation site

Key solutions

Climate Defense System: ▸ Intelligent delivery of desiccant based on container humidity prediction ▸ Phase change insulation material wrapping in extreme temperature zones

Smart Loading Technology:

▸ 3D loading solution improves space utilization by 37%

▸ Real-time tracking of container assets

Seamless Customs Clearance:

▸ Pre-customs clearance services in 27 countries

▸ Dedicated compliance manager escorts the whole process

Maldives case

Challenge:

No dock facilities + monsoon season

Scheme:

✅ Waterproof composite packaging

✅ Amphibious unloading equipment

✅ Modular installation process

"Blockchain material traceability system convinced the sustainability committee in 5 minutes" – Marriott's Asia Pacific Procurement Director

🛠️ Stage 6: Delivery as a Service

new starting point for cooperation

The completion of the installation is the beginning of the service

Performance Guardian Plan:

▸ Annual preventive maintenance

▸ 4-hour online response to urgent questions

Circular Economy Action:

▸ Refurbishment cycle furniture repurchase program

▸ Material passports realize full life cycle traceability

Create value

✮ 22% reduction in full-cycle holding costs

✮ Room renovation efficiency increased by 41%

✮ 100% meet Marriott's 2025 sustainability goals

Three core advantages

✅ Project gene sequencing - systematic control of 287 success factors

✅ Cultural melting power - the design team is deeply integrated into the destination culture

✅ Hassle-free scalability – simultaneous delivery of demonstrative capabilities across three continents

# Welcome to contact us #

Email: james@xinshiyifurniture.com

TEL: +86 18162199483

Whatsapp:+8618320742098

WechatID: 231561747

ADD:Furniture Industrial Park, Longling Town, Nankang District, Ganzhou City, Jiangxi Province, China.

- 2025-09-28Four Seasons Hotel Project Complete Process Guide

- 2025-09-12Xinshiyi Technology - Complete Guide to TownePlace Suites Hotel Furniture Project

- 2025-09-05Where to Buy Hotel Furniture? Ultimate 2025 Guide for Global Buyers | Xinshiyi Technology

- 2025-08-23Hilton Hampton Hotel Furniture One-Stop Solution | Professional Hotel Furniture Manufacturer

- 2025-08-22Villa Hotel Furniture Customization Complete Guide - Professional One-Stop Solution | Quality Furniture Manufacturer

- 2025-08-22Luxury Hotel Furniture Customization Service - Complete Guide for St. Regis Resort Project | Professional Hotel Furniture Manufacturer

- 2025-08-22Patina Hotel Furniture Project Complete Guide - One-Stop Hotel Furniture Manufacturing Solution

- 2025-08-17How to Choose a Professional Hotel Furniture Manufacturer | One-Stop Solution

- 2025-08-16Marriott Hotel Project Furniture Guide | End-to-End Hotel Furniture Solutions

- 2025-08-16XINSHIYI Hotel furniture manufacturer video show